Software: custom functions

|

Automatic vectorization of curves (ex. style lines):

|

|

|

Last's profiles:

|

|

|

Heel's profiles:

|

|

|

Flattening curves:

|

|

|

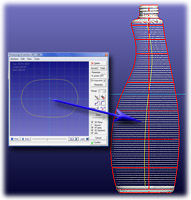

Cutting planes:

|

|

|

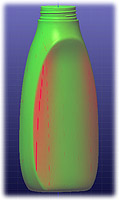

3D Quality control:

|

|

|

Packaging:

|

|

|

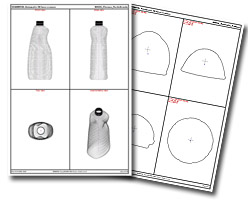

Print:

|

|